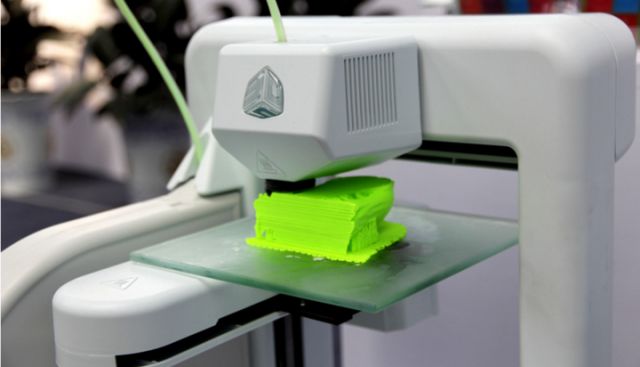

Additive manufacturing, commonly known as 3D printing, is the direct transformation of virtual digitized solid model into product, which greatly simplifies the production process, reduces the cost of research and development and shortens the research and development cycle, making the production of arbitrarily complex structure parts possible. At present, 3D printing technology is applied in automobile, medical, aerospace, industrial design, architecture and other fields.

The global additive manufacturing industry has basically formed a development trend dominated by developed countries and regions such as the United States and Europe, while Asian countries and regions are catching up. China initiated the research on additive manufacturing technology in the late 1980s. After years of development, the pace of industrialization was significantly accelerated.

According to the analysis report on the market demand and investment potential of China's 3D printing industry 2018-2023 released by the prospective industry research institute, since 2014, the size of China's 3D printing industry has been expanding continuously, reaching 1.67 billion us dollars in 2017.

The state has formulated a development plan for 3D printing, which will make 3D printing more intelligent, convenient and versatile

At present, the scale of China's additive manufacturing industry has achieved rapid growth. However, compared with developed countries, China's additive manufacturing industry still has problems, such as lagging of key technologies, insufficient innovation ability, urgent improvement of special material performance, improvement of quality reliability of high-end equipment and components, and improvement of application breadth and depth.

In 2017, 12 departments including the ministry of industry and information technology and the development and reform commission issued the action plan for the development of the additive manufacturing industry (2017-2020), and proposed to achieve five targets by 2020. Second, the technological level has been significantly improved, breaking through more than 100 kinds of technological equipment, core devices and special materials that meet the needs of key industries; Third, the industry application has been significantly deepened, more than 100 pilot demonstration projects have been carried out, and the large-scale application has been realized in the four major fields of key manufacturing (aviation, aerospace, ship, nuclear industry, automobile, electric power equipment, rail transit equipment, household appliances, mold, casting, etc.), medical treatment, culture and education. Fourthly, the ecological system is basically perfect to form a complete industrial chain of raw material manufacturing, and the ecological system, including measurement, standards, testing and certification, is basically formed. Fifth, the global layout has been preliminarily realized, more than 2-3 leading enterprises with strong international competitiveness have been cultivated, 2-3 international famous brands have been created, and a batch of equipment and products have gone to the international market.

At present, a new round of technological and industrial revolution is emerging in the world. All countries in the world regard additive manufacturing as a new growth point for future industrial development and promote the accelerated integration of additive manufacturing technology and information network technology, new material technology and new design concept. As the global manufacturing and consumption patterns begin to reshape, 3D printing will embrace great development opportunities. According to the analysis report on market demand and investment potential of China's 3D printing industry 2018-2023 released by forward-looking industry research institute, 3D printing will be more intelligent, convenient and general in the future.

Intelligent and convenient. Currently, 3D printing equipment still has many problems to be optimized in terms of software function, post-processing, seamless connection between design software and production control software. For example, support needs to be added in the molding process, different materials need to be used in the molding process, and software intelligence and automation are required to further improve the powder removal after processing. At the same time, as 3D printing technology is more and more widely used in clothing, design and life production, only when users feel that simple use, low technical threshold and low complexity during use can they have better user experience and popularize this technology more generally. This series of problems directly affect the popularization and popularization of equipment, and intelligent and convenient equipment is the guarantee of popularization.

Generalization. 3D printing has been a hot topic in the world in recent years. Its output device is called 3D printer, which is used as an external output device of a computer. It can be directly to drawing the 3 d design software in the computer graphics output into a three-dimensional color entity, in science education, industrial manufacturing, product innovation, industrial arts, etc have widely application prospect and huge commercial value, it also calls for 3 d printing technology to the direction of low cost, high precision, high performance.

Tel:15158365810

HTML:www.mysyqc.com

Add:No.185, bridge 3 road, xiaoqiaotou village, qiaotou town, cixi city